ARC Studwelding involves the same basic principles and metallurgical aspects as any other arc welding procedure.

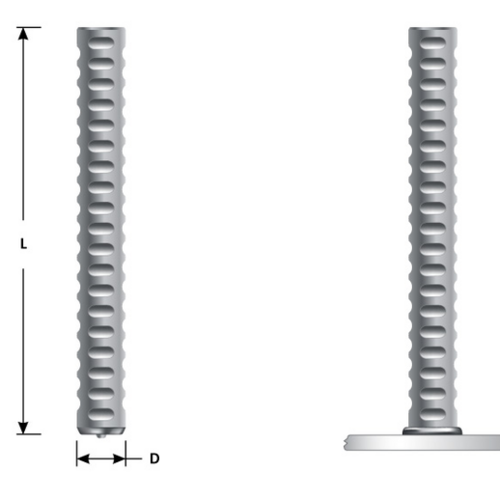

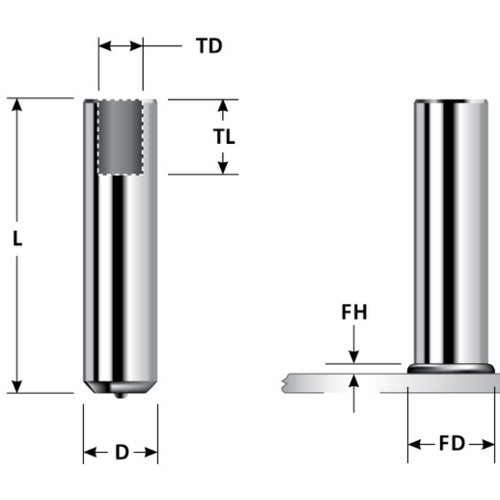

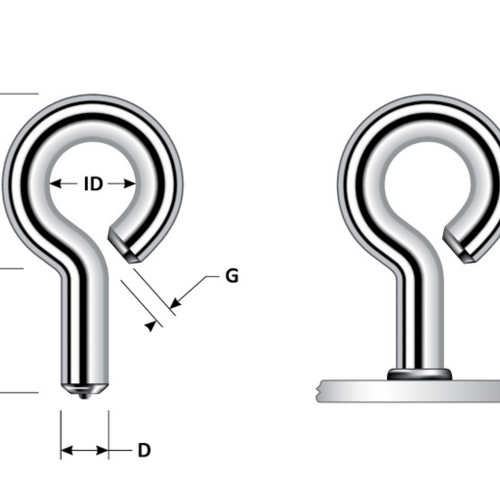

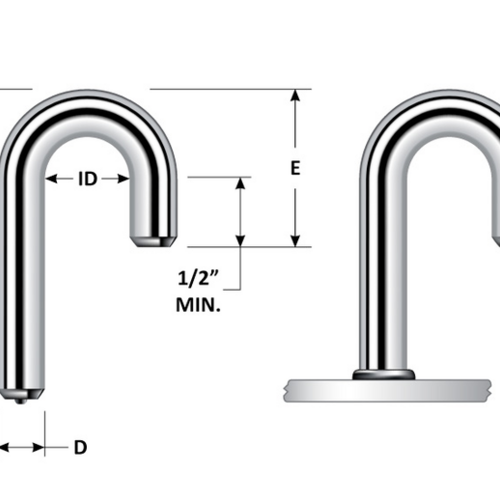

The weld gun lifts the stud a short distance from the base metal and initiates a controlled electric arc from the power source which melts the end of the stud and a portion of the base metal.

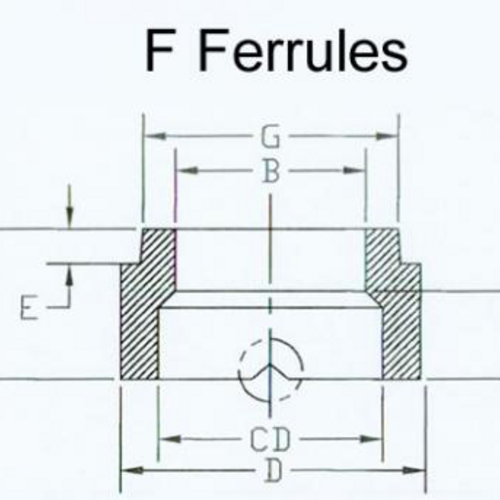

The ceramic ferrule or gas tube contains the molten metal into which the stud is thrust automatically and a high quality fusion weld is accomplished.

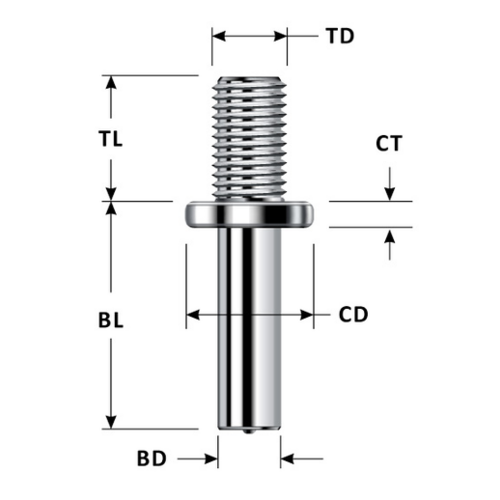

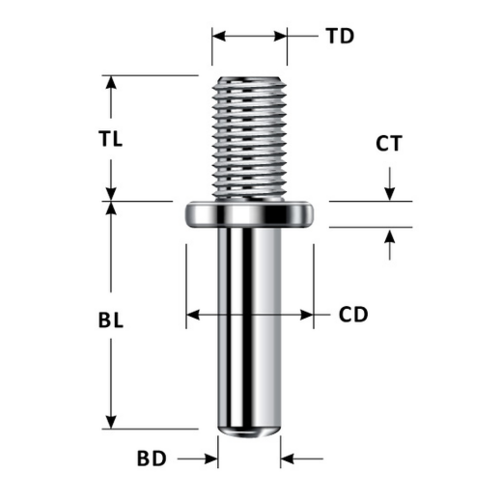

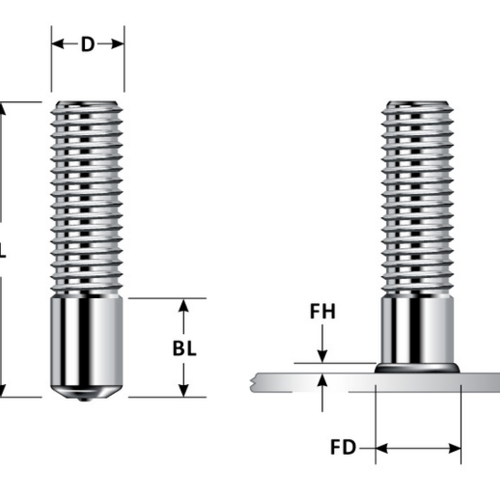

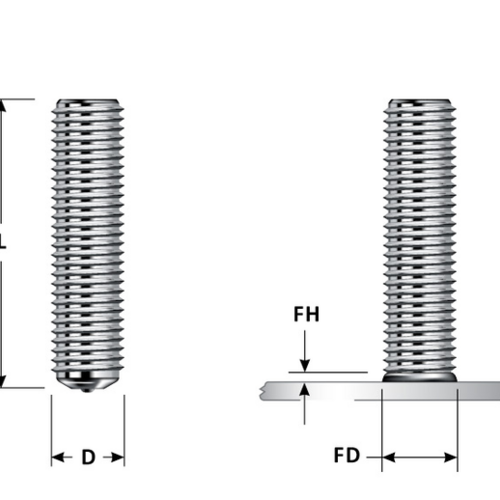

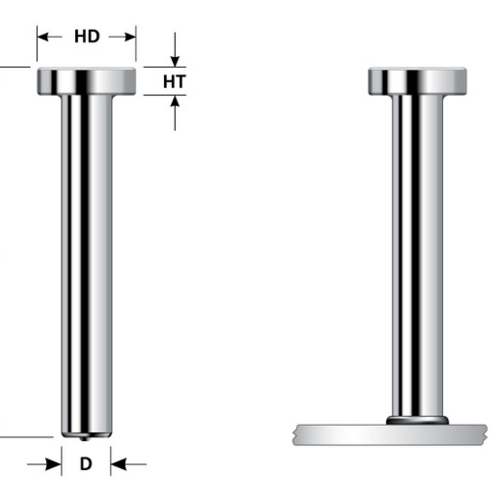

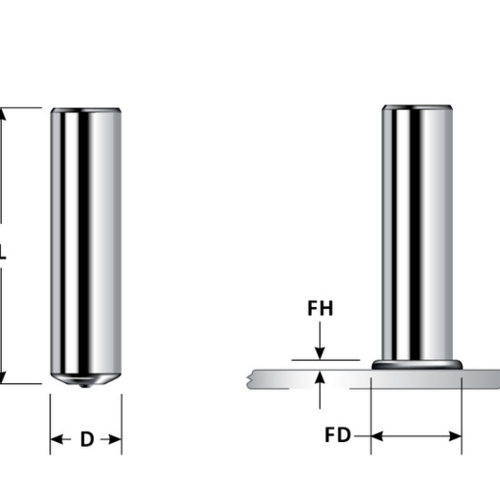

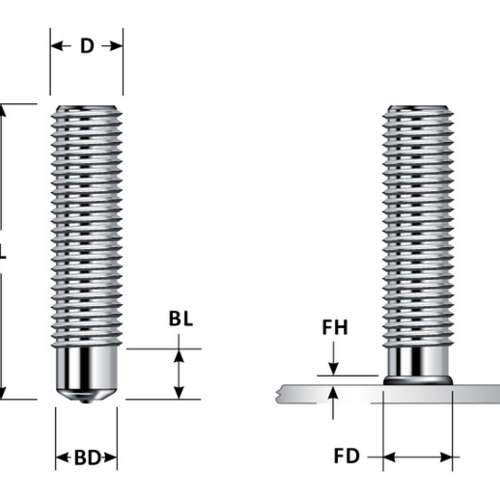

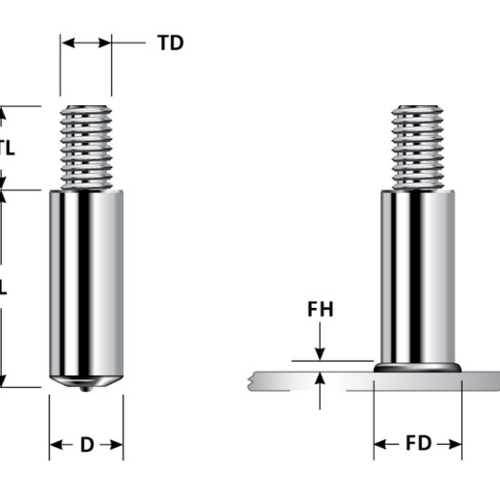

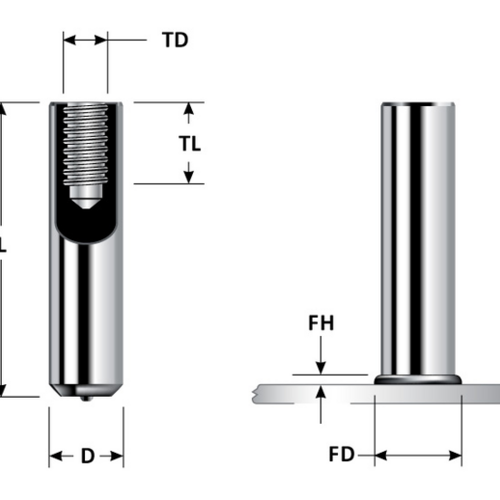

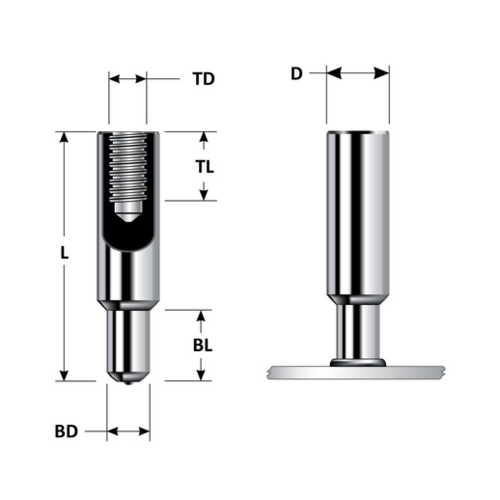

When an arc stud is welded, a fillet forms around its base with the fillet dimensions being closely controlled by the design of the ferrule used.

Please speak to your Jordahl team if you require further information.